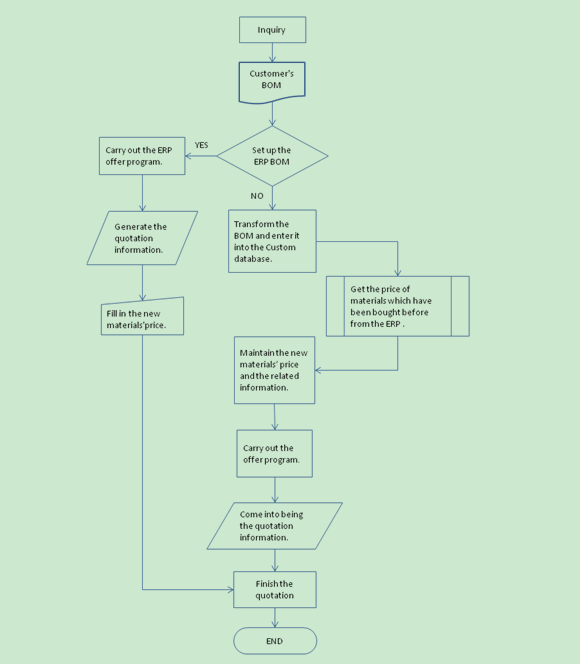

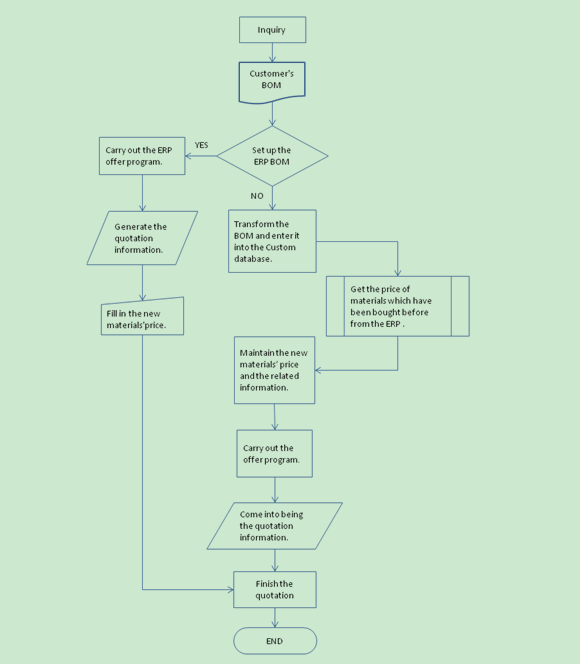

In order to meet the quotation needed by different customers, and let the customers to grasp the cost information of products and materials more quickly, PSI needs to generate the material quotations faster and more accurately.

Therefore, PSI has customized a process to operate the material quotations automatically to reduce the complicated manual work, which improves the work efficiency provides the service to customers in the shortest time.

The Offer operation mode is divided into the following three kinds:

A. The quotation for the products whose BOM has been set in the ERP system.

- PSI has established the complete customer BOM in the ERP system.

- For implementing ERP customization offer program, just need to type in the main part number of the products. Then it can produce the material quotation sheets immediately.

- The latest purchase price of the materials which PSI has bought before will be filled into the quotation sheet automatically.

- Automatically get the materials' MOQ, LT, manufactories and other related information.

- For the new materials without price in the quotation sheet, the purchasing department will fill in the price and complete the quotation sheet of material.

- New materials' price will be imported into the ERP system database, so that they can be used next time.

B. The work order quotation for the produced products because of the change of materials.

- The main reason for the change in quotation sheet.

- The scope of PSI purchasing materials or consign materials has been changed, where the materials' price needs to be updated.

- Changed ECN causes the materials to increase, decrease, or to be replaced, which needs to be quoted.

- Implement ERP customization work order quotation program, and generate material price list in accordance with the materials used in the work order automatically.

- Automatically get the latest price and related information of materials.

- The material quotation sheet will show the BOM material and usage, so it is easy for material confirmation.

C. The quotation for the products whose BOM has not been set in the ERP system.

- This is suitable for the product quotation which is not ordered temporarily. Generally, BOM is not set in ERP in advance.

- After the customers' BOM passes the format conversion, the material information will be put into each customer’s special database.

- Carry out the automatic program and update the latest price in the customers' special database based on the part number comparison table.

- After the procurement checking on the new price, the result will be implemented on the customer special database.

- New materials' related information, such as MOQ, LT, and manufactories, will be implemented on the customer special database.

- Carry out the offer program, directly produce the materials' price and related information in the customer BOM, and finish the quotation sheet.

- Purchaser inquiring on different batches' quotation according to different demand.

- After finishing a quotation, the information will be kept in the customer’s special database. With the accumulation of the information, it will be retrieved quickly in the following material quotation.

Quotation process: