The customer base has increased. The production models and the orders have multiplied. Coupled with the increasingly complex products, of course, technical documents related to transaction processing jobs has become more frequent, the number has also become more. So we must think about how to make work more automated in the industry, to ensure that the documents are obtained correctly and timely to do factory issues. It then can help the related production department schedule the production of correct products, which ensures the quality of delivery.

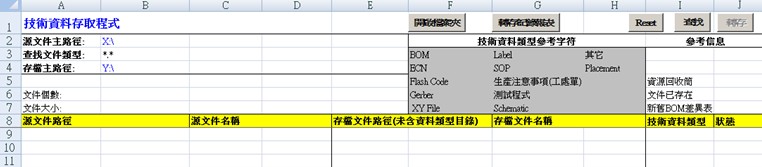

First, in the past we provided paper documents, now we provide electronic files. In addition to use less paper, thanks to the technology, the information can be transmitted faster. (Figure 1)

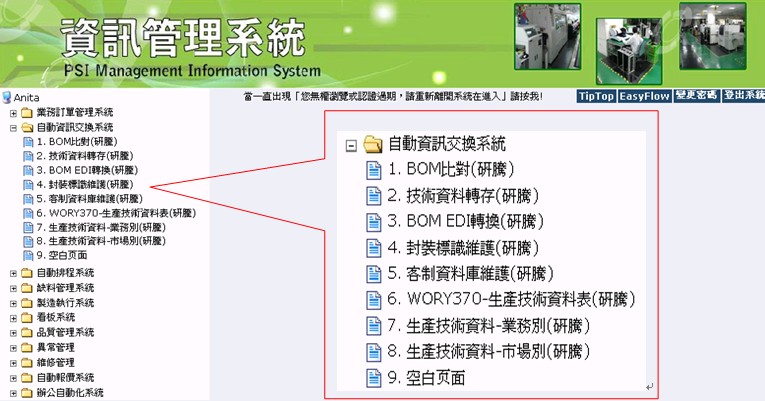

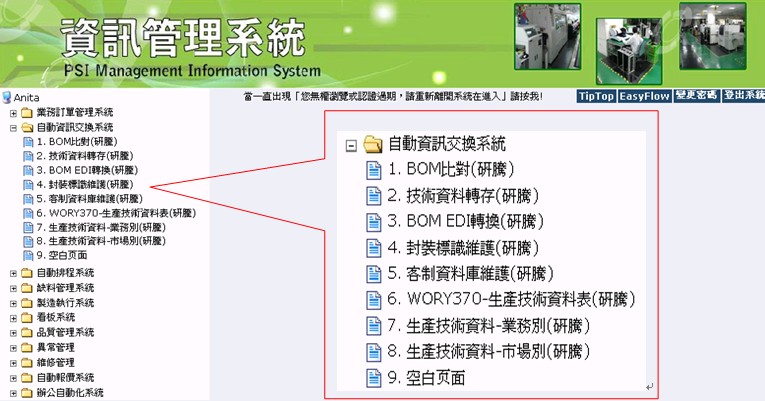

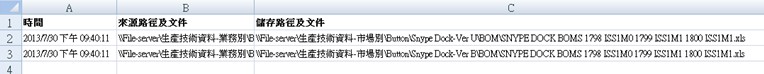

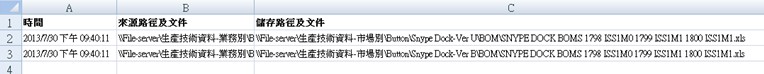

On the File-server a temporary storage area is set. Business personnel always firstly get the customers’ technical data files stored here. The documents are approached by the responsible officers in the market unit. They categorize the documents at 11:00 am and 16:00 pm daily. Through the self-designed auto-save program (Figure 2), the documents are timely, fast and accurately moved to the formal areas. The dump information will also generate reports archived for future reference (Figure 3). Urgent documents are ready to be processed at any time, to meet the need of the rapid changes in production line for the production scheduling.

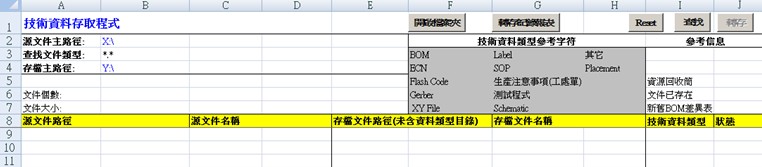

Through the electronic billboards, production related units have access to technical documents, which can be sorted by lines, aircrafts, and work order. They can also read the customer’s requested production notes, and the related shipping transport messages to ensure that all information is not missed. (Figure 4)

Due to a huge amount of data, in order to avoid abnormal power supply, computer equipment failure, or the effects of natural disasters resulting in data loss, and to ensure information security, network management unit will back up the data in a different place regularly.

(Figure 1)

(Figure 2)

(Figure 3)

(Figure 4)