The Introduction of MIS Automatic Management System

for Testing, Assembling and Packing

for Testing, Assembling and Packing

Author: Victor Wang

Management Information System is the full name for MIS, which, combining with ERP System, forms the enterprise resource management System. The detailed introduction of the MIS (how to manage automatically for the production of testing, assembling and packing) is described below:

The MIS system in the production management is divided into electronic billboard system, data collection system, and manufacturing execution system.

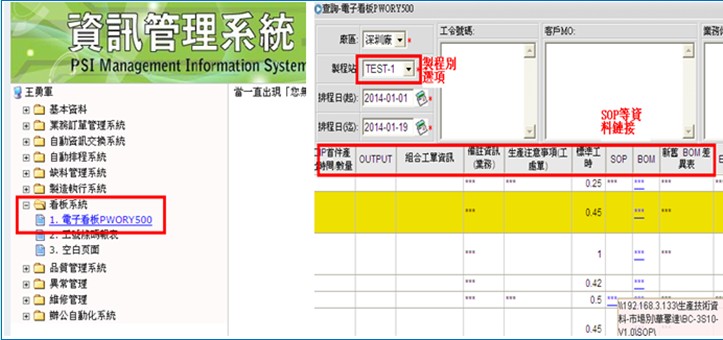

NO.1 Electronic billboard system

- How does the electronic billboard system work? After the PSI market gets the related information about production from the client, they can store the data to the server, and also store the path into MIS system at the same time. The company units can log in the MIS system by using a PC, through hyperlinks on the electronic billboard, to acquire the required production BOM, the group package work instruction, production notes and other production related materials.

NO.2 Data collection system

- Data collection system is based on the work order, customer, models and other categories. By the Nai Feng I-DAQ data terminal equipment, Data collection system transmits information, such as the start and completion time of the real-time product production, the product volume completed, and number of the bad product, to the server database. Therefore the customer or company can check the status of the related products.

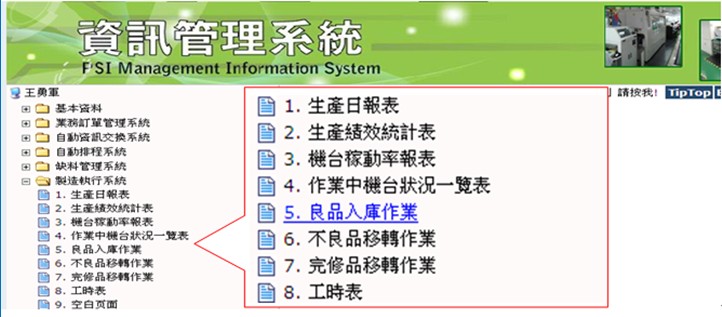

NO.3 Manufacturing execution system

- Manufacturing execution system is a system composed of daily production report, operation machine status table, production performance report, work time table, ERP stock transfer system and production management system.

- ■Daily production report

- The daily production report is produced after finishing the background server operations .It contains information of work orders, customers,

models, numbers of good/bad product, working efficiency and other information. - ■Production performance report

- The production performance report is produced by the background server’s operation. It reflects different models’ production input time

and efficiency report. - ■Work time report

- Through the ERP system users can find out the customers’ product types and its production time .It is convenient to plan the production

schedule and capacity assessment. - ■Operation machine status table

- It confirms if the collection of Nai Feng data import terminal station status works well. Also the operation machine status table can reflect the

situation of production scheduling (such as how many customers models in production). - ■ERP inventory transfer system

- ERP inventory transfer system contains good storage products and bad products transfer system. It is mainly carried out in the background

through the combination of ERP system. Even when not logged in the ERP system, users can complete transfer lists from different process

and different state database.