First Source Recommendation

Author: Peter Pan

The components choice is an important issue of design end in the development process. After the creative formation of product, the designers have to start looking for the components used for the company to design the next generation of more competitive products. Because the design/production/sales processes are currently working in professional divisions, the original components in design stage always need an approved substitute, in order to get better MOQ/Lead Time / Price and reduce the products cost in the production stage. At this point, if the product has gone through a series of functional tests and safety certification, changing specifications of the part will not be easy. It will cause obstacles in production difficulties and also affect the product sales capacity.

We have long been aware of our role in the customers’ EVT / DVT / PVT stage during new products development phase. In addition to provide designs for manufacturing report (DFM Report) and also to provide "Components Database" to the clients, towe hope clients choose our components of specification and brand that has been used by us in mass production for their new products development stage. It will be able to reduce the unnecessary component changes and problems in substitute proposed for approval. The description of our practice is listed below:

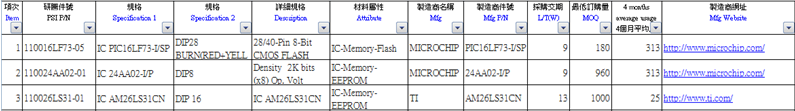

- General practice: Provide the "Components Database" quarterly and then email to every customer for reference and use. Currently, the list include IC, transistors and diodes. The categories in the list will be gradually extended in the future. An example content of the database is listed below.

- Project practice: When the customers make requests, they can provide us the BOM of new products in design phase and we will build a project to provide the proposed substitutes. For general components, we search from our component database to provide clients substitute of approval. As for major components, we would find components of more competitive specification and manufacturer and ask clients for substitute approval. If the recommendations of the component size or pins specification are different with the original source, clients will need to make the evaluation and modify PCB Layout design.

At the product design stage, we work closely with clients, provide design suggestions, components selections and other services. Therefore, clients will be able to understand the problems of component used and solve them at the same time during the designing phase. It is duty-bound task for us. We hope that through our services, we can shorten the time of design, production and sales phase and launch the product successfully. We make the clients’ satisfied and reach a win-win situation.