The Application of the MIS System in the Engineering

and Technical Management

Author: Victor Wang

Industrial development has gone through three revolutions. Recently, the German government has proposed a high-tech strategic plan, “Industrial 4.0”. It is the fourth industrial revolution. The main goal is to make use of the coupon information system (Cyber – Physical System CPS). It make the information of production, manufacturing and sales “digital” and “smart”. So that we can finally achieve rapid, effective, and personalized product supply. PSI also keep up with the development of the industry, and gradually design their own information management system. Here I’d like to introduce the application of the MIS system in engineering and technical management briefly.

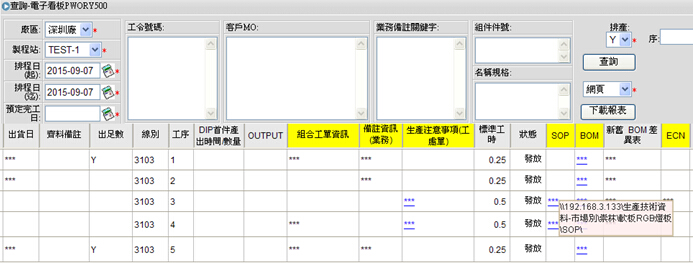

1. Get the production information

In Kanban system, we can review specification, production notes and considerations by searching the process, date, working order and so on, accessing the production model of information database. So the manager will train the testing personnel according to the information.

2. Test the function of products

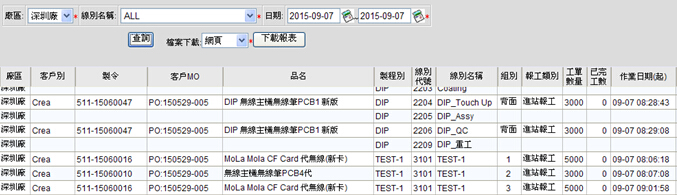

| 2-1. | The foreman will load the working orders, lines, quantities and other related information in the data center of the MIS system through the IDAQ data collector when we are in production. When the production is finished, the foreman will also use the IDAQ to upload the production information and conditions to the database according to the test report (and we will use the SN to track & control the defective ones). |

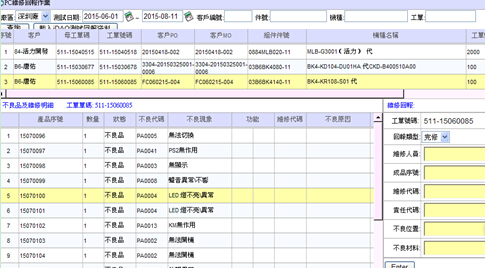

| 2-2. | Then we will login the test data maintenance system from PC terminal, and upload the defective information (mainly for the S/ N, defect code) to the MIS system data center |

3. Dysfunction recondition

When maintenance department received defective products, they will do the dysfunction recondition according to the relevant specifications and produce the maintenance report (SN number and defect code, maintenance code, and responsibility code are included). Next they will login maintenance return system through the PC terminal, and upload the maintenance result in the system.

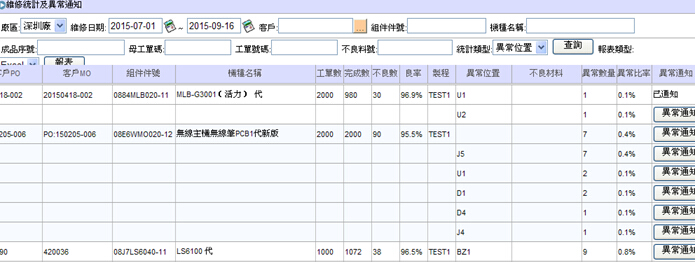

4. Feedback of Anomaly

Engineer will login the maintenance management system to check the defective conditions by the working order. If the same problems appear at the same time, the system will automatically send the notice. So the related department will receive the anomaly information and they will analyze and improve the condition.

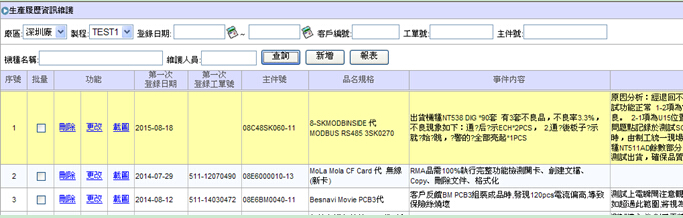

5. The production record

When the anomaly is detected, the engineer of the department needs to record the process of the occurrence and make improvement plan after analyzing in the system. When the same model is in production again, engineering personnel can find the records of production history in the Kanban system. So that they can remind the operator in the following production.

6. The query of history records

Relevant department can check the bad condition of the old orders in production by the function of maintenance report query.