Optimization for Work Construction System

In recent years, the rise concept of industry 4.0, with the rising salary, manpower shortages, product delivery time is getting shorter and shorter, how to immediately grasp on-site production dynamics and response instantly has become very important.

PSI is already implemented the work construction automatic system in May 2015, due to the current customer orders are in the low volume and diverse type, how to make the work construction action easier and more accurate in production data that is an important issue for us. So, we continued to optimize this work construction system and changed the more complex action to a simple operation, and let our production people more convenient in the operation. Relatively, improve the accuracy of the work construction. And then through the "MIS-work construction

system" and connect with "ERP- work order transferred operation " that it can be finished together from the work flow in production line to the semi products (finished products) transferred operations for every process to achieve the process flow automation goals.

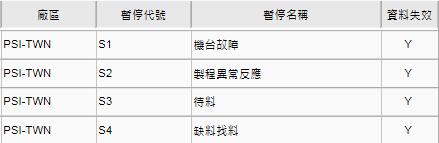

The beginning of the implemented of work construction system is also having a lot of problems, but after discussed with IT team on the actual situation from the “Work construction started (start production)Pause (sudden situation in production) Work construction stopped (end production)Work order transferred operation (production quantity linked to ERP)Efficiency review” to revise the system many times and optimize program that the new revision system can be finished and implemented into production.

The benefits generated by the following:

- In / out of the station, the system provides more complete information on the work order and operate work construction system easier.

- From machine failure, abnormal process response to the out of station of final manufacture, the total working time is managed by the system.

- Provide production information status in time and let managers can monitor and analyze the utilization rate and capacity at any time. And also, the information can be referred by sales for receiving customer’s orders and confirmed the shipping delivery if it can meet customer requirements.

- The working construction data can be transferred into production efficiency. We set a standard of 90% -110% (the low standard cannot be less than 90% and the high standard is not higher than 110%) reviewed by weekly for checking effectiveness and self-improvement.

- As a result of the working construction system automation that it is also reduced the amount of paper and close company goals for paperless.

The following introduction of PSI working construction system:

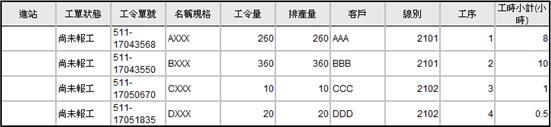

- In of the station (start production): To scan the barcode number of work order and production line.

- Pause: For the emergency situation in production.

- Out of the station (End production): To input the manpower and production quantity.

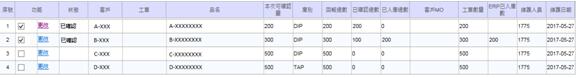

- Work order transferred operation:

- Efficiency reviewed: Reviewed by production line and product for lower than 90% and higher than 110%.