The Automation Process of Material Receiving

in Pronology Services (China) Inc

In the 11 years since we founded Pronology Services (China) Inc., for 11 years, there are many manually working have been replaced with automation process. Our warehouse is no exception on this situation. We created the automation process of material receiving too. Compare with receiving the material by manually, automation process have the following advantages:

- Realize the material handling automation and reduce the labor cost.

- Ensure the efficient and accurate when we pass the material to IQC department do the incoming inspection, and prevent defective.

- Realize the informatization of material management process to reduce management difficulties and improve the efficiency.

- Improve working efficiency through FIFO information system. At present, PSI has automated material receiving and pass to do the inspection, using the Web-Pad and scanner to scan the bar code of part number and PO number. And then, to automatic transfer these data to ERP system, to realize and to be sure our MIS system and ERP system have a real-time data exchange system

Here have a simple step instruction as following descriptions:

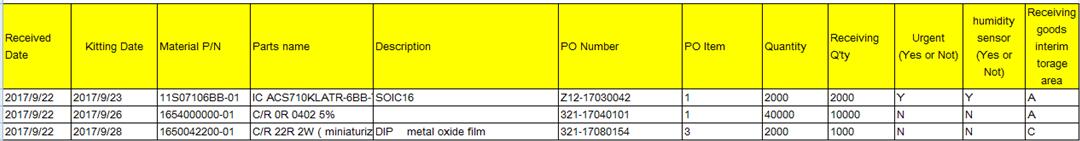

- At first, in order to let our IQC staff simple and efficient to find which one need do the inspection, the area of the corresponding materials will be arranged in the warehouse temporary storage area, so that the IQC inspection can make the materials more convenient.

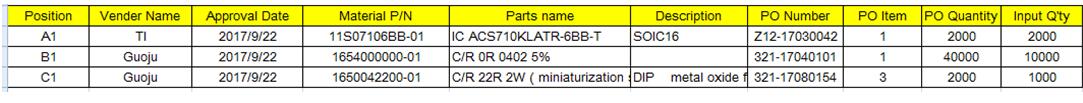

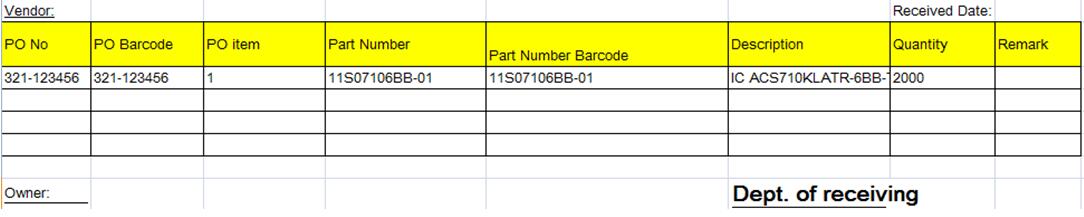

- Scanning the Part Number corresponding to the PO bar code as per the receipt of vendor

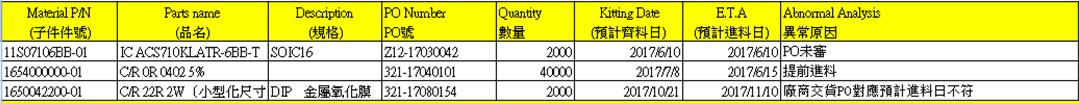

- We will scan the barcode of our material number on the delivery sheet, the operation system will take out of the materials information by automatically, like as quantity/estimate day/moisture sensor Component, etc. at the same time, our ERP system will determine whether it's a wrong PO, whether coming date too early, whether it's an urgent case, etc, will list the result and show them on the display once after calculate.

- It will prompt and more quickly to note according Department and tracking the action when the abnormal detain or it have any abnormal notice be happened. The operation system will sent the email automatically to the relevant department for processing.

- If the required material is a super urgent item system, it will be sent to the relevant Dept. for processing every 2H automatically.

- When the warehouse automatically receives the goods, can intercept the advance charge, control the company's turnover status.

Quality assurance inspection:

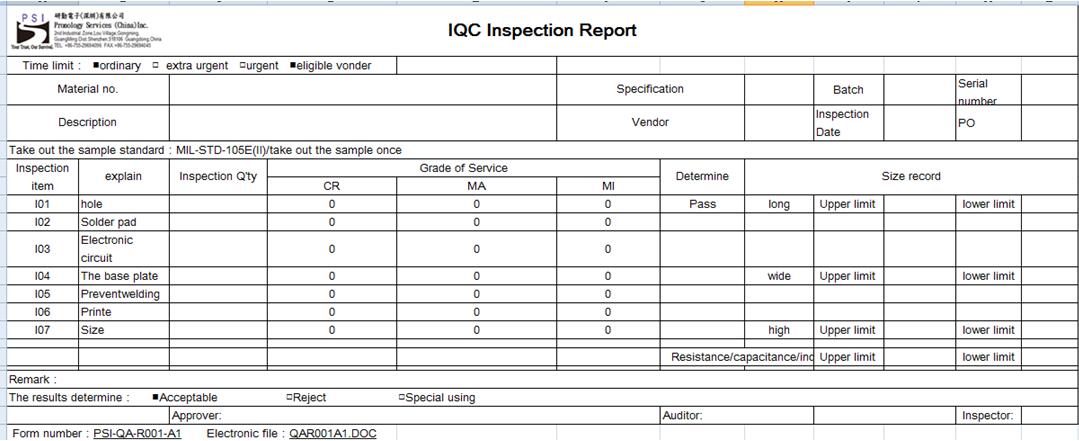

- When the material is swept into the system by the warehouse, it will be automatically sent to the product protection program by the system, and the reminder should be tested. According to the special dispatch, the urgent item and the general material will be reflected in the program.

- The QA will maintain the inspection items in the system, and will automatically bring out the standard items to be inspected in the inspection materials.

- System will automatically generate inspection report after inspection OK.

- The quality assurance system automatically sends a reminder to the warehouse collector for the inspection of the day, and the report is as follows: