The advancement of DIP automation in 2021

Author: Alex

Importing from manual separator to routing machine allows customers to perform board splitting operations according to the special splitting requirements of each model.

Routing machine:

- PCB placed on the platform of the machine, use the dedicated thimble to fix on the screw hole of PCB, make it positioned (if multiple linking board need to create a dedicated vehicle, then operate).

- Using high-resolution color CCD camera lens to write the path to be cut.

- Finally, use of high-precision high-speed servo motor, carry with a dextrorotation form tungsten steel milling cutter to segment PCB board.

Advantages: It can cut to irregular shape, produced the minimum stress, dual-platform increase production efficiency, so PSI bought and set up the "Routing separator" in order to achieve the standards and quality of the customer. The production line also continued the education training to workers in order to write programs and assignments, now already can import on-line work. And get the original technology, manpower counseling, let us encounter any situation can immediately communicate, handle and solve in the production process, and we will not let the production action interrupted.

With the Routing separator and the original V-cut separator (one blade moving; two board moving machine), enough to deal with all the current PCB board, let the problems produced by "stress damage" bottom out.

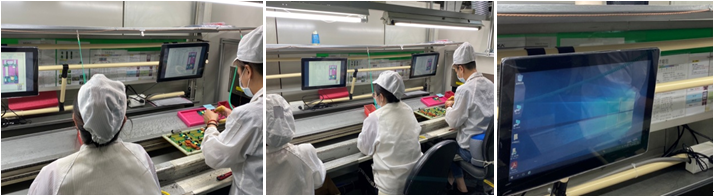

Importation of e-SOP and real-time work construction:

In mid-June 2021, many ipad have been installed on the Line A plug-in, and e-SOPs have been introduced successively, allowing personnel to change from paper black-and-white SOPs to e-color SOPs, and personnel can more clearly know the part number and plug-in location at the top of the screen in the process of making SOP. Engineers only need to change the content of SOP, instead of printing it out and putting it in the BOM. It can effectively reduce the use of paper and achieving the goal of paperless.

With the introduction of e-SOP, the accuracy of the staff plug-in can be effectively improved, and the special needs prompted by customers can be reversed in SOP, so that DIP production operations are clearer and more standardized, and better production quality services are provided.

DIP instant report and visual inspection system:

In mid-November 2021, the plug-in line introduced the instant report & visual inspection system. In the original operation process, the plug-in personnel placed the parts on the PCB according to the SOP arrangement. The QC personnel performed a 100% visual inspection at the final inspection station in front of the furnace to confirm whether there are missing parts, wrong parts, reverse, and other issues. After confirmation, you need to install the bead to fix the parts to ensure that the parts will not be skewed or raised during the furnace. Therefore, the role of the general inspection is very important. If the furnace is not inspected, problems will inevitably result in poor quality and increased costs.

Therefore, PSI has introduced a real-time report & visual inspection system in front of the plug-in line furnace. On the one hand, it uses the system to report the job in real time to monitor the output efficiency at the remote end, and the system automatically compares the image with the master. Detecting the appearance of PCBA, replacing the error of the general inspection station personnel. If the PCB has a laser engraving serial number, it can also be combined with the visual inspection result. When subsequent quality problems occur, it can be traced back, query the current inspection status, analyze and improve production line efficiency and furnace yield.

In the end, as the times change, Industry 4.0 automation is more than that. We are still committed to continuous development such as production automation, high-end pressing equipment, and many other developments and implementations. In 2021, it is the transformation of PSI. In the past year, PSI will also provide customers with products, quality, delivery, and service that are always satisfactory to customers. It is also hoped that the partners who cooperate with PSI now and in the future can grow together and spread their wings.