Quality Assurance Abnormality and Operation Management Platform

Author: James

The PSI communication between units or with customers is mainly through E-mail, resulting in hundreds of E-mails received every day, including daily operations of each unit or abnormal and urgent events that need to be dealt with. In the process of reviewing hundreds of E-mails, personnel are prone to negligence, and they cannot see the emails for processing immediately. Based on the above factors, we have developed a system by ourselves to build a platform to integrate information, so that operators can display information through the platform. The immediate handling of work items at a glance can also reduce the occurrence of exceptions, reduce processing time and costs, and cancel the email exception notification at that time, reducing the number of emails per day, which is the so-called "quality assurance abnormality and operation management platform".

Through the planning of the abnormality and operation management platform, the operations that usually need to be executed or managed are incorporated into the platform, so that personnel can obtain the daily to-be-processed items from a system screen or process them through the system prompts, shorten the time to read E-mails, reduce the risk of unread emails, and improve the work efficiency of personnel. You have more time to conduct online audits to prevent abnormal occurrences and speed up abnormal analysis and processing time, and so on, and improve the quality control of the production process.

Following is the plan of quality assurance abnormality and operation management platform:

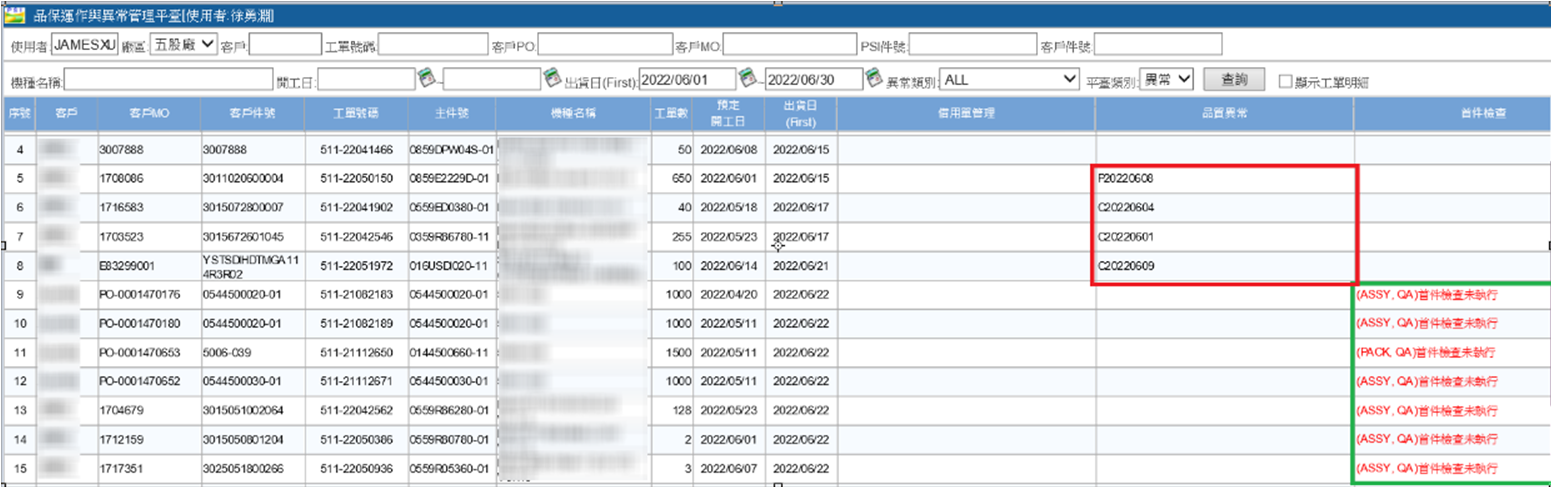

- Items that are planned to be included in the management platform, such as quality abnormality, first article inspection, etc. (the yellow box in the figure below)

- Display the to-do items to be executed (the green box in the figure below)

- Display overdue items (the red box in the figure below)