PSI lead-in anti-error operating system

Author: Colin Cheng

PSI has been planning and implementing the automation and paperless management of the company's internal work process, and the self-developed MISplus system, linked with the ERP system data, established a small number of diversified product production management mode.

With the increase of PSI customer base over time, the frequency of production line changes every day. In order to reduce the chance of mismaterial on production line, PSI established a mismaterial prevention system in the MISplus system through the efforts of the IT department.

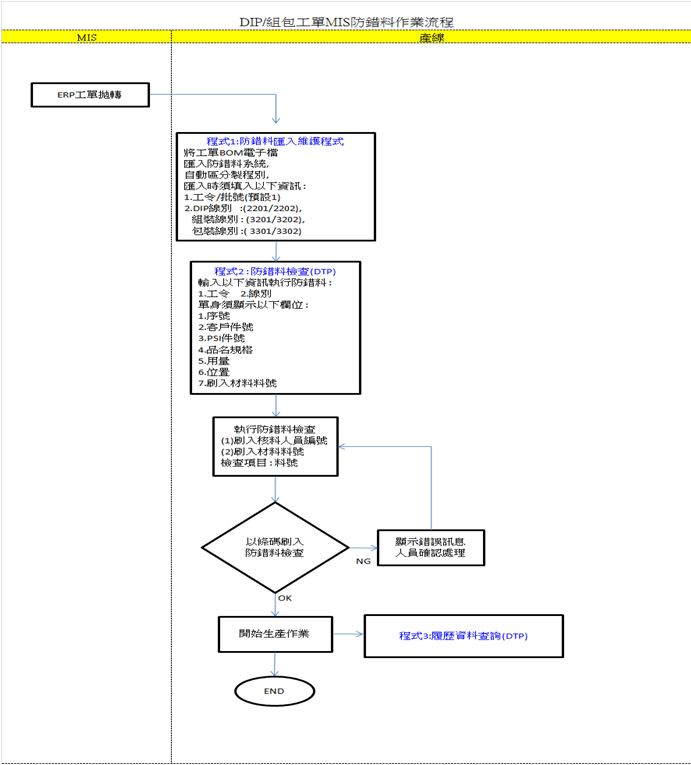

The following is a brief introduction to the work flow of the anti-error material system:

- ERP work order rotation shall be performed in MISplus system

- Use program 1 "Fail-proof Material Import Maintenance Program" to import the electronic file of the work order BOM into the fail-proof material system, and the fail-proof material system will automatically distinguish the process.

- Use program 2 "Fail-Proof Material Check (DTP)", input "work order" and "line classification", at the same time, use the code gun to brush in the verification personnel code and material number, and the fail-proof material system will automatically determine whether the brushed material number belongs to the work order material, so as to ensure the correctness of the material used in the work order. When the material number is inconsistent with the material number required by the work order, the anti-error material system will display an error message, requiring the material verification personnel to reconfirm whether the material is correct or not.

- Use program 3 "History Information Query (DTP)" to query the history of the anti-error work order data.

Attached Figure 1: Operation flow chart of anti-error material system: