Safety inventory management of production accessories (consumables)

Author: Paul Shu

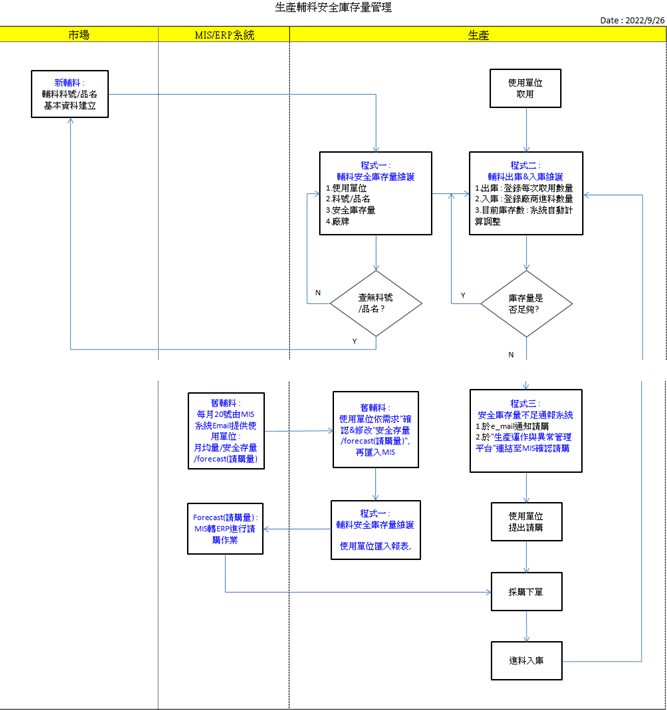

In response to the increasing variety of production consumables, the importance of inventory management, and the production operation mode of multiple factories, in order to meet the needs of production line production consumables, safety stock management and paperless application for procurement, PSI will be launched in 2023, we began to think about the automation of the requisition process for production consumables, replacing manual writing on paper and the planning of manually entering requisitions into the system.The specific method is as follows: (Please refer to Attachment 1 for the flow chart of safety inventory management of production accessories)

In the original method of requisitioning production consumables, the applicant unit manages the inventory of consumables by itself. When the consumables are running out, the handwritten paper purchase requisition will be submitted to the unit/department supervisor for review and signature, and then handed over to the general affairs staff to manually transfer the data. Input to the purchase requisition system, and then the procurement system will place an order to the manufacturer according to the needs of the requisition unit. It is estimated that the manual processing process will take about 30 minutes.

Introducing the automation of the purchase process of production consumables, on the one hand, it can save the time of the above-mentioned manual work. Through the system, the monthly average amount of consumables used in the previous 6 months can be used to automatically determine the quantity to be purchased each month in the future, and at the beginning of each month automatically place orders (the demand for the next month) to the manufacturer; on the other hand, it can prevent the production line from forgetting to apply for consumables due to personnel negligence, resulting in the dilemma of being unable to produce and affecting shipments.This automated process is expected to be implemented in June 2023.

Importing automatic management and execution from manual operations can save a lot of operation time and achieve the goals of labor cost savings, stable production delivery and paperless. We look forward to improving our work efficiency through the introduction of production auxiliary materials safety stock management, and accurately grasping the quantity of consumables requisitioned and reducing the error rate of personnel execution.