Add consign-material into system

Author: Paul

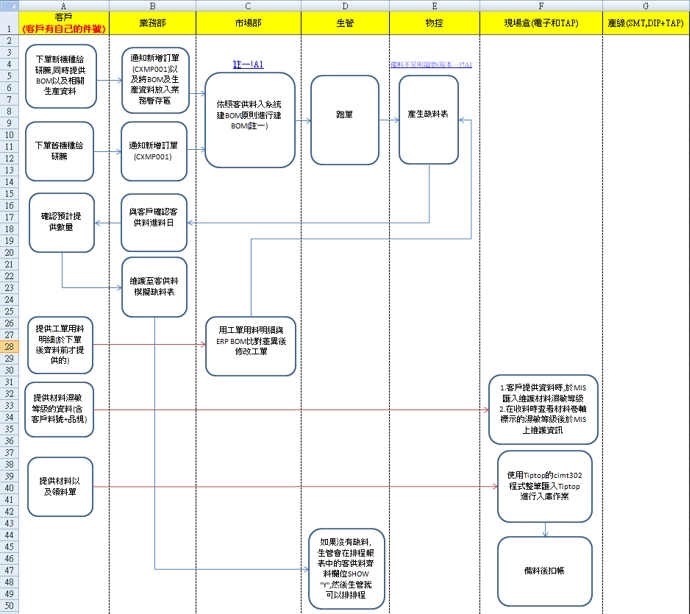

In response to the increasing number of customer groups, orders, and machine types, and in the small-volume and diversified production model, in order to effectively manage the inventory materials provided by customers and quickly understand the shortage of materials required for each production order, PSI began to think about it in 2024. The automation of consign-material into the ERP system management replaces the use of the MIS PLUS system, which is only used to manage inventory and cannot be linked to each order to instantly grasp the specific shortage of materials. The specific methods are as follows:

The original inventory of consign-material used the work order picking details list provided by the customer to prepare materials and deduct accounts. When there was a shortage of materials, the customer was notified by email through manual processing, and the missing materials were collected from the customer and returned to the factory. It is estimated that the manual processing and email notification process for sending materials will take about 15 minutes.

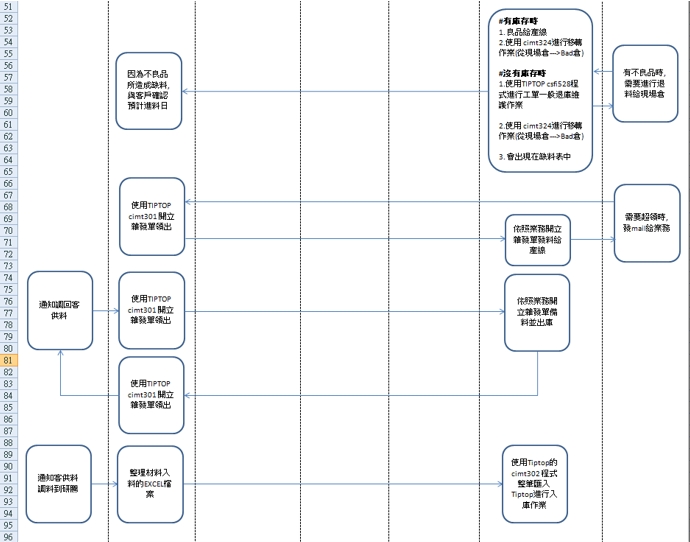

By importing consign-material into the automation of ERP system management, on the one hand, the time for the above-mentioned manual work can be saved. The ERP system automatically calculates the material shortage of each order every day and automatically sends customer-supplied simulated material shortage list information notifications. PSI allows customers to check the material shortage status of each order internally and through the real-time system. This automated process is expected to be implemented in January 2025.

Switching from the MIS PLUS system to the ERP system for automatic management and execution of customer supply can save a lot of work time, achieve the goal of saving labor costs and instantly grasp the shortage of materials in orders. We look forward to the introduction of customer supply into the ERP system management. Our work efficiency has improved and we can accurately grasp the shortage of materials in orders.