Application of PSI-CN DIP AOI Pre-wave soldering

Author: Paul Liu

As the designs of products in the electronics industry become increasingly sophisticated, and the quality demands continue to rise, the global surge in artificial intelligence and automation has led to more refined and user-friendly automated equipment that replaces manual operations. In the electronics sector, the challenges associated with manual visual inspection of PCBA in the DIP plug-in segment have increased, resulting in lower efficiency. The introduction of AOI (Automated Optical Inspection) visual inspection devices to replace manual inspection can effectively prevent issues such as incorrect parts, missing parts, and reversed components. This systematic and comprehensive approach significantly enhances the production yield in terms of efficiency and precision. The wave soldering AOI equipment can at least substitute the workload of 1-2 manual inspectors, substantially reducing labor costs, improving repair efficiency, and lowering production operational costs, thereby generating greater benefits.

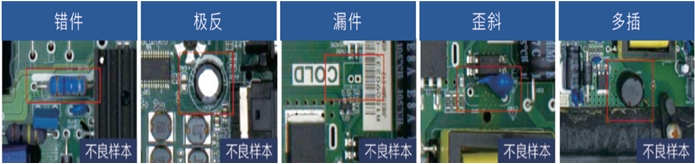

In alignment with the above directives, PSI-CN will implement DIP plug-in AOI starting in 2024 for the detection of missing, incorrect, reversed, misaligned, and multiple inserted components on circuit boards. It will also support the detection of incorrect color-coded resistors, applying specifically to inspections prior to wave soldering. The primary advantage of this system is its ability to replace manual visual inspection operations before the oven, enabling more precise and effective identification and interception of defective items, thus preventing them from entering the wave soldering equipment and causing actual defects.

AOI Model: AIS SERIES 200; the main features are as follows:

■ SPC Statistical Analysis: Provides real-time, practical statistical data and a variety of analytical charts to assist with quality analysis and decision-making;

■ Process Traceability Function: Supports barcode scanning and integration with MES systems, allowing for real-time output and tracking;

■ Multi-Panel Inspection: Can simultaneously inspect various PCB boards, automatically invoking the corresponding inspection programs, thereby enhancing production flexibility;

■ Defective Product Display: Auditory alerts provide sound notifications for defects; visual prompts highlight the defective locations; red frames focus attention on the locations of defective items, increasing processing efficiency.

In actual production operations, the AOI equipment identifies defective items and their locations, allowing on-site personnel to respond quickly to alarm notifications and manage issues swiftly, thereby further enhancing quality and efficiency.

In April 2025, Client A visited our company coinciding with the production of their products. The customer personally input defective items into the production line. The AOI equipment quickly and accurately identified the defects and provided voice alerts. The operators followed the standard procedures for entry, repair, and re-inspection through AOI. The overall performance left a deep impression on the client, who highly commended and appreciated the implementation of the DIP pre-wave soldering plug-in AOI for enhancing quality. This accomplishment was highlighted as a key feature and a positive aspect of their visit.