Instant work report and Deviation notification

Author: Peter Pan

In modern manufacturing, real-time information, production automation and intelligence have become the core elements for improving production efficiency and quality management, and they are also an important part of the digital transformation of enterprises. As early as the first half of 2015, the automated reporting system was fully introduced to PSI, but manual entry and exit operations were still required in the system. Due to the Small-volume Large-variety model, the number of work orders is small and the number of items is large, which often leads to problems such as personnel missing work reports, delayed reporting time, wrong reporting quantity, information asymmetry, etc.

In order to solve these points, PSI launched the second optimization of the reporting system in 2023, emphasizing immediacy and a more automated method to establish a complete "production instant work report and deviation notification" system to solve previous reporting problems, thereby quickly grasping the production progress and conducting production scheduling through exception notifications in real time without affecting customer shipment needs.

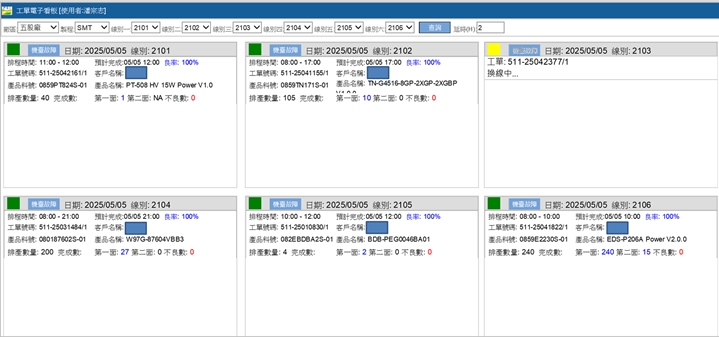

The first step in establishing a reporting system is data collection. Taking the SMT production line as an example, unlike the traditional practice of setting up automatic sensors on the assembly line to count the production quantity, we use the existing automated equipment "SPI solder paste inspection machine" on the production line. In addition to performing the original solder paste printing quality monitoring, we have added the function of collecting. By pc production time and uploading quantity to MES. Through the " electronic Kaban " developed by our IT (as shown below), whether the company colleagues are inside or remote, they can view the current production progress and quality of each process & line through this real-time reporting system.

Normal operationchanging linemachine failure

The production status of the work order is delayed for more than 2 hours

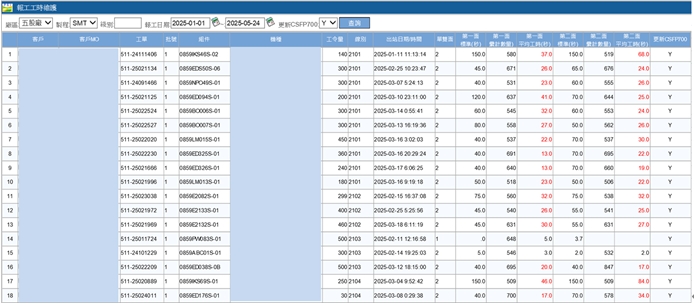

After collecting these work report data, the correct standard working hours for each machine type are established in the system through data analysis and statistical methods. This is different from the traditional IE method of measuring working hours on the production line and then establishing it in the system. It is completely established in the MES system through automated equipment and data analysis and statistics (as shown in the figure below, the standard working hours are established in real time).

After the standard working hours are established for each machine model, when production abnormalities occur, you can receive instant abnormality notifications through the system and cellphone push notifications, including "production working hours delay abnormality/standard working hours abnormality/efficiency abnormality"... etc. (as shown in the figure below), and management personnel can immediately make production adjustments and subsequent analysis, review, and improvement actions.

The establishment of this real-time reporting system not only reduces human errors and provides instant notification of abnormal reporting, but also improves production transparency, speeds up response, and supports subsequent automated scheduling APS, which has become one of the company's goals in continuously promoting smart manufacturing. It is hoped that through the establishment and operation of this system, production efficiency will be gradually improved and costs will be reduced, making the company more competitive in the EMS electronic professional OEM service field.