AOI visual inspection and real-time anomaly notification

Author: Peter Pan

In modern manufacturing, product dimensions are becoming increasingly precise, assembly speeds are accelerating, and customer demands for quality are rising. Traditional manual visual inspection is not only time-consuming and labor-intensive, but also prone to errors and omissions due to fatigue or subjective judgment. To address this issue, many factories have implemented AOI (Automated Optical Inspection) systems to perform visual inspections in a highly automated manner. Following the previous introduction to "Applications of DIP AOI" and "Instant Reporting and Anomaly Notification," this issue further introduces how to extend the functionality of DIP AOI to include instant reporting and anomaly notification mechanisms.

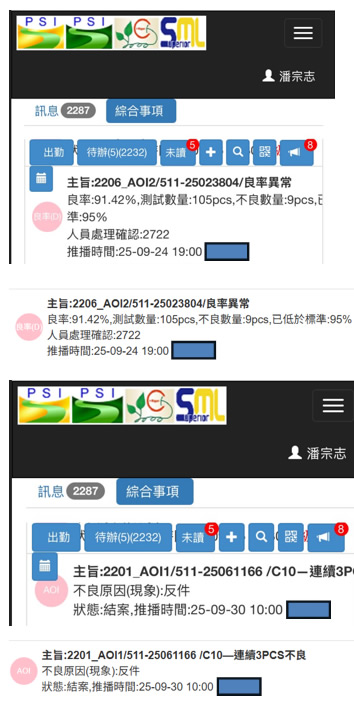

Previously, the company's PCBA appearance inspection in the DIP process relied on 100% manual visual inspection. Production information acquisition was also limited to manually written reports, followed by statistical analysis. However, when production anomalies occurred, information was often not received immediately, resulting in missed opportunities for improvement. Fortunately, since 2021, the company received a government AI application subsidy. After planning and implementation, a production information system for the production line was completed. The system uses AOI equipment to output information for real-time reporting of work data and collection of test records. This has been further developed into an app for anomaly notifications on mobile devices. During the production process, real-time production progress can be obtained remotely. When a continuous defect occurs in the current process, an anomaly notification can be received via the app.

After collecting real-time work reports from DIP AOI systems, the information system compares them with the current production schedule to confirm whether the production line is meeting targets. This allows managers to monitor remotely in real time and automatically adjust the production scheduling system to optimize the entire production process and meet customer delivery deadlines. The system can also calculate production time for each product model to establish standard working hours for real-time efficiency management.

(The image below shows the real-time production progress dashboard for the DIP line.)

After collecting DIP AOI test records, the information system immediately performs statistical analysis. If the test yield is lower than the set standard value or the same defect occurs continuously in the same work order, the system will immediately issue an anomaly notification through the mobile APP, allowing process engineers to go to the production line to confirm the defect and implement improvement measures immediately to prevent the defect from spreading and improve the overall production quality.

(As shown in the image below, abnormal notifications are sent via a mobile app.)

By combining AOI visual inspection with a real-time anomaly notification system, not only is production more intelligent and information acquisition more automated, but production efficiency and quality are also significantly improved. Preventing batch defects and reducing the number of defects are the company's ongoing goals, thereby reducing the failure costs incurred by retesting in subsequent processes and repairing defective products, enabling the company to obtain more profits for sustainable development, and making the company more competitive in the EMS electronic OEM/ODM service field.