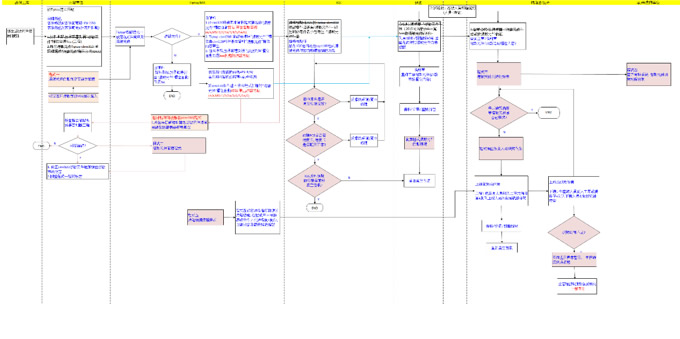

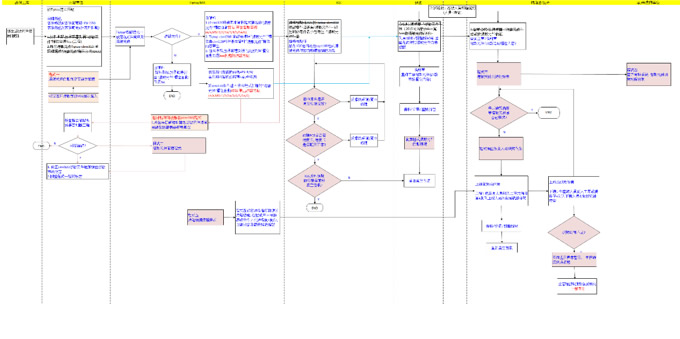

Automation Procedure for Humidity-Sensitive Component Controlled Process Coming Soon

Author: Steven

After some meetings between the engineering colleagues of the marketing department and colleagues from relevant departments, as well as the IT colleagues to discuss the detail specifications of the procedure and feasibility adjustment, as well as the unremitting efforts of the IT colleagues, the Humidity-Sensitive Component Controlled Process Automation Procedure has now entered into the testing stage, and will soon be put into use.

Compared to the previous process, the automation procedure will add the following functional items,

1. By setting rules, the procedure automatically determines the level of humidity sensitive components.

2. Add batch importing function of customer humidity sensitivity level MSL database.

3. Digitize the baking record sheet for humidity sensitive components, and the procedure will automatically remind the operators of the baking operation.

4. Automatically determine and allocate ovens based on the baking temperature of humidity sensitive components

5. Add customer real-time system - humidity sensitive component baking record query function.

2. Add batch importing function of customer humidity sensitivity level MSL database.

3. Digitize the baking record sheet for humidity sensitive components, and the procedure will automatically remind the operators of the baking operation.

4. Automatically determine and allocate ovens based on the baking temperature of humidity sensitive components

5. Add customer real-time system - humidity sensitive component baking record query function.

The above added functions will further improve the automation of the operation of each department involved in the entire Humidity-Sensitive Component Controlled Process Automation Procedure.

We will work with our IT colleagues to complete the debugging and functional acceptance of Humidity-Sensitive Component Controlled Process Automation Procedure as soon as possible. Accelerate the automation and optimization of the process, and improve the establishment of customer’s Humidity-Sensitive component database. Let customers and our colleagues to have real-time access to the status of humidity sensitive components, and devote themselves to providing more efficient and quality guaranteed services for customers' products. Let's look forward to its coming!

Figure 1. Flow Chart for Automation Procedure for Humidity-Sensitive Component Controlled Process